wilson debuts 3D-printed airless basketball prototype with hexagon holes

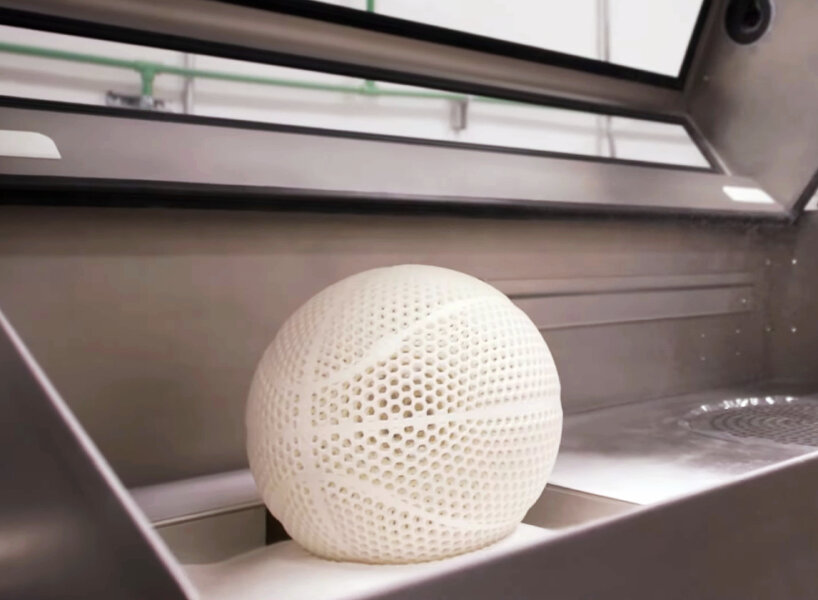

first prototype of a 3D printed airless basketball

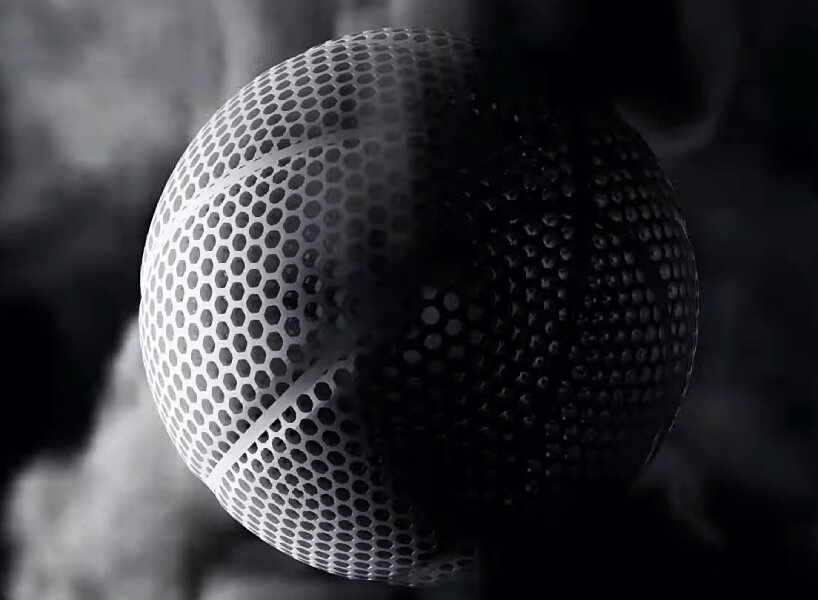

The sporting goods manufacturer Wilson Sporting Goods has presented its Bouncy 3D printed airless basketball Prototype featuring hundreds of hexagonal holes during the first round of the AT&T Slam Dunk Contest on February 18, 2023. NBA player KJ Martin tested the bouncy airless basketball to see if it felt and performed like a regular basketball that used in games courts.

The black-colored hexagonal dot basketball rebounds seamlessly from and to the player’s hand and the ground without any air, while Wilson searches for innovative sports equipment with less maintenance and through new technologies like 3D printing. Wilson’s 3D printed airless basketball prototype eliminates the need to inflate the ball every now and then.

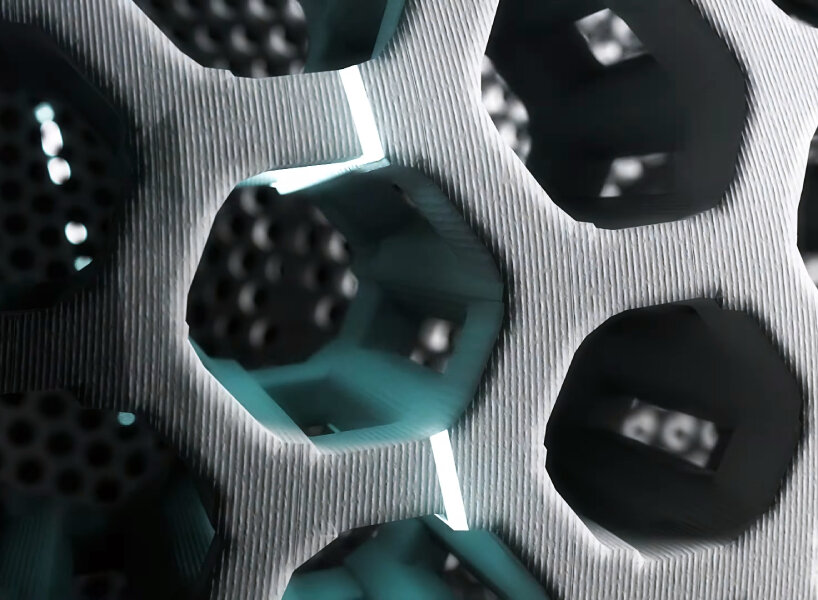

The design team relied on a 3D-printed lattice structure and research-grade materials to recreate the bounce of a traditional basketball. The surface of the ball is encased with small hexagonal holes to allow air to pass freely and support the spring. The ribs of the airless prototype feature the well-known seam structure of a normal basketball, along with eight plate-like nubs. Wilson sees its recent development as a spur for the company to develop the same design elements for other ball-related sports.

Screenshots courtesy of Wilson Basketball

How did Wilson create the prototype?

The 3D printed airless basketball prototype from Wilson sporting goods started with a bed of white powder and a laser that etched the sphere’s hexagonal design horizontally into the powder. As the pattern stacked up, the 3D printed airless basketball came to life, and the team dusted off the mass of white powder that bathed it. The team sealed the powder in the 3D structure using another machine before dipping it into a dyeing machine, turning it from its mere white color to an all-black hue.

Wilson worked with EOS, a 3D printing solutions company, to make airless basketball a reality. The company admitted that collaborating with Wilson on a 3D printed basketball is different from their usual endeavor as they primarily work with aerospace, automotive and medical companies for 3D printing. But EOS believed they could help Wilson bring airless basketball to life.

3D printed hexagonal holes

More tests will follow

Rigorous testing followed for the first prototype to ensure it would bounce and feel like an air-filled basketball. Wilson says there is still work to be done before the 3D printed airless basketball hits commercial stores and basketball courts as the initial release is just a prototype, but the ability to make such an item and hopefully commercialize it, is something the company is clinging to.

Wilson’s design team, which includes engineers, developed several designs before settling on the 3D printed hexagonal hole airless basketball prototype. Their goal was to achieve a basketball-like look, feel, and function like a basketball. They also thought of the player the team believed helped make the prototype a reality, because if a player didn’t love the way an airless basketball felt and performed, production wouldn’t get the green light.

Rigorous testing will follow to ensure the airless basketball matches the players’ game

The hexagonal holes allow air to flow freely and help the ball bounce