How To Cut Acrylic Sheet With Table Saw

Eighty teeth to the inch will leave a nice smooth cut. Just like the plastic was a piece of wood, turn on your saw and run the acrylic sheet over the blade.

How to build a Perspex box Perspex, Acrylic box, Acrylic

How to build a Perspex box Perspex, Acrylic box, Acrylic

Since acrylic is finicky, you’re going to want to play with the saw’s speed and your feed rate to see what works best.

How to cut acrylic sheet with table saw. A table saw is the easiest way to cut through a sheet of plexiglass or other acrylic materials, it has its drawbacks as well, since plexiglass is a thermoplastic, it needs some special handling. Scoring preferably works on sheets less than ¼” (6.35mm) in thickness. I wonder how should i do it on a table saw.

In order to do so, i will frame a sheet of plexiglas (1/8 thick) in wood. How to cut acrylic sheets. Then arrange the straight edge so it's just slightly on the line and clamp it to the work surface.

Push the acrylic through the table saw at a steady pace, being sure to keep your fingers out of the way of the saw. To make straight cuts on thicker sheets of acrylic and polycarbonate plastic (greater than ⅛ inch thick), you’ll need to use a table saw or circular saw. It is not a difficult task to cut an acrylic sheet with the help of a circular machine saw.

Once the sheet has been scored, clamp the acrylic on a table edge so that the table edge aligns with the scored line of the sheet. Adjust the table saw fence to 12 inches. For table saw cutting acrylic, a carbide tipped blade with a minimum of 80 teeth is required.

Mark the area of sheet you want to cut. Be sure to pick one that has fine teeth and at least ten of them per inch. To make an interior cut in acrylic with a jigsaw, you will need to drill a pilot hole so you can have a starting point for your jigsaw blade.

Clamp the sheet if needed. Extruded acrylic has a lower melting point than cast acrylic and a cutting fluid or compressed air should be applied to cut to keep heat build up to a minimum. Because of the flexible nature of acrylic sheeting, light hand tools like the dremel can be a better option than heavier power tools.

You can also do a test cut on the waste side of the acrylic sheet to see how it goes before working on the final cut itself. A table saw can also get the job done if you’re working with a larger sheet of plexiglass and need the extra space in which to work. Cut the plastic using the table saw.

Since most people use a table saw on wood or sheet metal most of the time, they don’t know how to cut plexiglass with a table saw the right way. For cutting straight lines, the circular law works best; Start at one edge of the mark you made.

You just have to hit the nail to the head. With the help of a dimmer, you can control the speed of the saw and it will make easy to do your task. Once you’ve “scored” your acrylic sheet several times, move your cut line to the edge of a sturdy table or counter.

Blades designed for plastics and nonferrous metals are ideal. For thicker sheets of plexiglass, cut with a power saw—be it a circular saw, saber saw, or table saw. These will cut finer but much hotter, and they aren’t necessary to get a clean cut.

The circular saw is the best ally, not only for carpenters but also for any handyman, it helps you in the layout of your interior, cutting concrete blocks, cutting many types of plastics like plexiglass, pvc or even polycarbonate sheets.however, the circular saw is nothing without quality blades. Check to see where the blade of your scoring tool will land when you run it against the side of the straight edge. If you find yourself in this category, it’s understandable why working with acrylic might be a scary thought the first time.

I now need to cut it to length. Use blades designed specifically to. (to cut anything but a straight line, opt for a jigsaw.)no matter which type of saw you.

Lay your acrylic sheet on a flat work surface, and mark the line to be cut. Wondering how to cut perspex (or acrylic glass) easily? Next, hold the sheet firmly on the table with one hand, and press the overhanging section down toward the floor.

Don't move too quickly, as you'll create a rougher edge, but don't go too slowly, as you can melt the plastic. However, keep in mind that you should only use this method on acrylic sheets that are 1/4 of an inch thick or thinner. I couldn't find a sheet with dimensions close to what i need, so i bought a bigger one.

When cutting plexiglas® acrylic sheet on a table saw, a cutting board should be used for cutting stacked/clamped material or making a cut not parallel to another edge (angle cut). I don't need a perfect cut. A thermoplastic is a kind of plastic that can be melted down again and repurposed.

Incorporating glass into a woodworking project can add an interesting design element, but it can be an expensive proposition to have glass cut to a custom size by a professional to match the specifications of your project. Once you confirm the clamp is secure, apply pressure to the piece of sheet that is hanging off of the table until it breaks off. Acrylic sheet can be cut with many different tools, but using a dremel with the appropriate attachments can make the process fairly simple.

If the cut was deep enough into the sheet, there will be a clean edge. Making an interior cut in an acrylic material: With some firm and steady pressure, the sheet will cleanly snap right along the line you scored.

When cutting perspex at home, you're more or less limited to using circular saws and jigsaws. Start the saw and carefully feed the sheet straight into the blade, cutting at a rate of about. Push the acrylic through a table saw for a straight cut.

For curvy lines, you'll want to use your jigsaw. Learn how to cut acrylic sheets with a table saw, safely and effectively. Figure 2 shows a suitable cutting board.

Use scoring knife to cut a narrow groove in the acrylic sheeting; Bend the overhang side of the sheet with quick and even motion. The plexiglas sheets have thicknesses that vary from 1 mm to 20 mm, which is why we will adapt the cutting method according to the desired thickness.

In either case, it’s of the utmost importance that the blade you use is suited for the task;

Pin on Organization Tips & Storage Ideas

Pin on Organization Tips & Storage Ideas

Panel saw, Plastic sheets and Build your own on Pinterest

Panel saw, Plastic sheets and Build your own on Pinterest

Pallet Tool, Woodworking Ideas Projects Drill Design

Pallet Tool, Woodworking Ideas Projects Drill Design

Nesting Sawhorses Compact, Strong & Easy To Make

Nesting Sawhorses Compact, Strong & Easy To Make

Bora Speedhorse 1500Pound Capacity Sawhorse PM4500

Bora Speedhorse 1500Pound Capacity Sawhorse PM4500

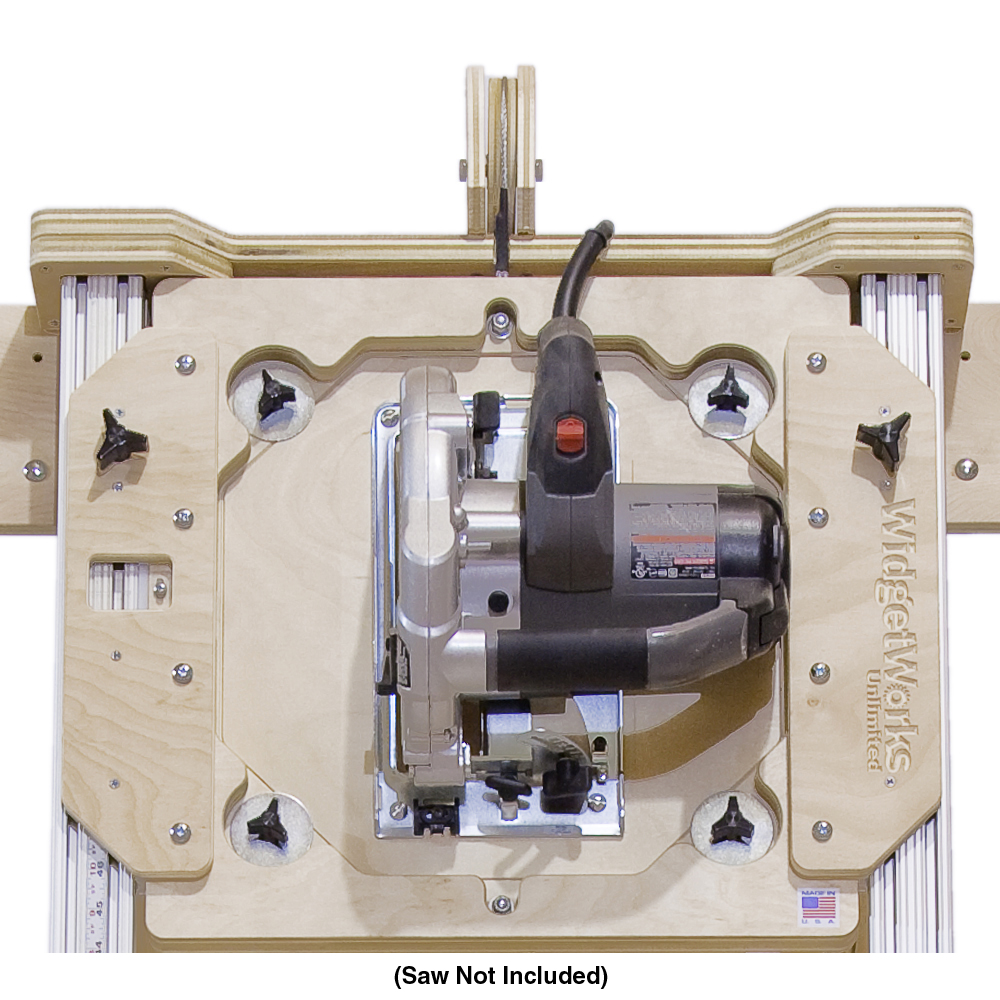

DIY Panel Saw Kit Build your own panel saw accurate to 1

DIY Panel Saw Kit Build your own panel saw accurate to 1

Router Rails Smooth ANY Surface Completely Flat

Router Rails Smooth ANY Surface Completely Flat

Corrugated plastic table Repurpose Pinterest Plastic

Corrugated plastic table Repurpose Pinterest Plastic

Pin by Jefferey Hunsucker on Router table

Pin by Jefferey Hunsucker on Router table

How To Make Circular Saw Crosscut Jig Mistry MakeTool in

How To Make Circular Saw Crosscut Jig Mistry MakeTool in

12" Metal/Plastic/Paper/Film/Sheet Sheer Table Top Cutter

12" Metal/Plastic/Paper/Film/Sheet Sheer Table Top Cutter

Panel saw, Build your own and Woodworking plans on Pinterest

Panel saw, Build your own and Woodworking plans on Pinterest