How To Measure A Screw Diameter

Measure the length of the screw with a ruler. Lay a steel rule between two screw threads and measure across the diameter.

Bolt Dimensions Metric bolt sizes, Bolt, Metric

Bolt Dimensions Metric bolt sizes, Bolt, Metric

3) effective or pitch diameter.

How to measure a screw diameter. Shop for us machine screws You can also measure from the bottom cavity of the threads from one side to the other to find the minor diameter. Measure what's known as the major diameter, which is from the top of a mountain on one side to the top of the opposite mountain directly across the screw.

How to determine screw size & thread count lay the screw down on a flat surface. Measure across the head of the screw to get the diameter. Hence, a number 12 screw is larger than a number 4 screw.

The pitch of the screw gauge is defined as the distance covered by the screw when it makes one complete rotation between the consecutive threads. The nominal length of a screw is usually, though not always, measured from below the head to the tip of the screw. Measure the diameter of the screw's shaft with your calipers.

Let's say for our screw the length is 2 inches. To measure diameter of a given wire using screw gauge. It's easiest to measure this with a caliper, but you can also measure it with a ruler.

Divide the count of thread gaps into the length. Count the number of thread gaps within 1 inch of the screw. To measure the length of a screw, one must simply measure the distance between one end of a screw and the other.

Measure from the top of the flat head to the tip of the screw to get the length. Let's say that at the widest point of the screw thread it is 1/4 of an inch. Measurements equal 0.060 + 0.013 x measured diameter.

How to measure screw thread size inch. For those with a diameter smaller than 1/4, screw size is indicated by a number (e.g., #10 or no.10). Measurement of various elements of thread to find out the accuracy of a screw thread it will be necessary to measure the following:

The fastener diameter is almost always the thread diameter (or major diameter). Measure the thread length and write it down. 4) pitch 5) thread angle and form 11.

On a standard m5 screw, for example, the grooves are 0.8 mm apart. For most purposes, that's all you need to know. A screw’s major diameter shows the screw’s diameter as measured from tip to tip of its threads, and in this table, we’ve included the minimum and maximum measurements a screw can be to be classified as that size.

Then, linear scale reading (l.s.r.) = n. It is important factor in how to measure screw sizes to note that there is no direct link between the strength of an imperial screw and its head size. This number will help you determine whether a screw will thread into a certain bolt properly.

Machine screws are manufactured with tolerances measured in thousandths of an inch. * nominal thread diameter is measured on the outside of the threads per asme b18.6.3 for more information about how to measure diameter see our measuring fastener diameter page. For this you measure to the wide point of the side of the thread.

If with the wire between plane faces a and b, the edge of the cap lies ahead of mb division of linear scale. To measure the diameter of screws and bolts, you measure the distance from the outer thread on one side to the outer thread on the other side. Now that you know the length of the screw.

Because this is approximately the same as the major or thread diameter the thread diameter measurement can be used for fully threaded bolts. Count how many threads per inch are there. All you need is a steel rule to determine the size and thread count of any screw.

Screw size is measured in diameter. The pitch diameter is the average of the screw’s width between its threads and grooves. I) total reading = msr+csr where msr = main scale reading csr = circular scale reading and, … continue reading to measure the diameter and volume of a given wire using a.

Place the shaft of the screw in between the jaws of your caliper. Use the head diameter and length to find the gauge of the screw on a screw chart, available at most hardware stores. The measurement of the screw on the thread.

Now we know the length and diameter. Inch thread sizes are specified by diameter and threads per inch. It is usually either 1 mm or 0.5 mm.

Place a steel rule down the axis of the screw. Read the first letter of the size. Measure the diameter of the screw's shaft with your calipers.

The diameter of a bolt is the shank diameter, expressed in millimetres for metric bolts. Simply holding the screw against a tape measure or ruler may not give you a measurement that is accurate enough for a proper fit. Start measuring from the bottom of the rounded top.

This means the larger the number, the larger the diameter. For more information on measuring the length of screws, see our article how to measure the length of a screw. Diameter is also known as screw size.

The actual diameter of an m3 screw is usually about 2.9mm, an m2.5 screw is 2.4mm and an m2 is 1.9mm. However, dependent on the type of screw, length can be measured in one of two ways. Place the screw on a flat surface.

A thread gauge resembles a spark plug feeler gauge. Yes, an m5 screw will have a diameter of 5mm. It may be measured from under the head or the overall length.

Aim to measure diameter of a given wire using screw gauge. Measure the shank length and write it down. The next step is figuring out the diameter of the screw.

Spread the lovegrab other class xi physics practicals from here. M8 is 8mm thick, and so on. Machine screws are manufactured with tolerances measured in thousandths of an inch.

Head diameter it is common for people to refer to hex bolts by the size of the head measured across the flats (this is also the size wrench the bolt uses). To measure the diameter and volume of a given wire using a screw gauge. To measure diameter of a given wire using screw gauge.

Measure the thread pitch with a thread gauge. The diameter is the width across the screw or bolt. Below is the experiment on how to measure the diameter of a given wire using a screw gauge.

What this means is that a screw considered to be 8 mm long may actually measure 7.6mm or 8.0mm. For the vast majority of machine screws, the nominal length is measured from below the head to the tip of the screw. First, the strength of the screw is the diameter.

Screw gauge, a thin wire and a metre scale theory: This is called the major diameter and will usually be the proper size of the bolt.

pilot hole size chart What is the best technique for

pilot hole size chart What is the best technique for

Wrench Conversion Chart for SAE & Metric Sizes Metal

Wrench Conversion Chart for SAE & Metric Sizes Metal

Pilot Hole Drill Bit Size Chart for Wood Screws Drill

Pilot Hole Drill Bit Size Chart for Wood Screws Drill

You never know when you have to drill a hole for a bolt

You never know when you have to drill a hole for a bolt

Metric Screw Thread Chart Tooling, Inc. Axial Thread

Metric Screw Thread Chart Tooling, Inc. Axial Thread

This nuts…….. and bolts Screws, bolts, Nails, screws

This nuts…….. and bolts Screws, bolts, Nails, screws

Wood screw sizing chart. Standard Shop / Wood

Wood screw sizing chart. Standard Shop / Wood

Wood Magazine's Screw Chart (Traditional Wood & Production

Wood Magazine's Screw Chart (Traditional Wood & Production

Metric Hex Head Bolts Metric bolt sizes, Engineering

Metric Hex Head Bolts Metric bolt sizes, Engineering

Chart comparing standard screw / nut / hole sizes

Chart comparing standard screw / nut / hole sizes

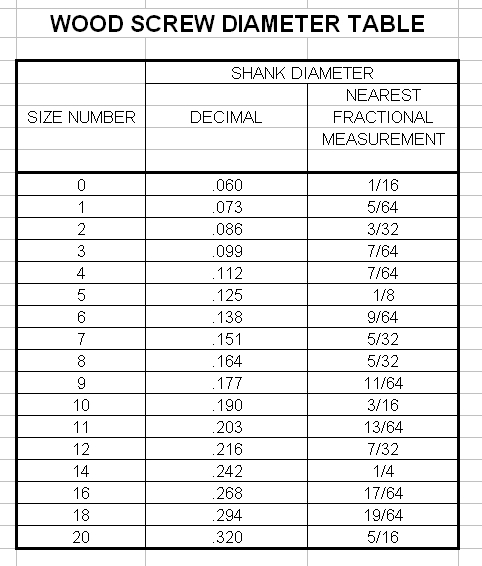

WOOD SCREW DIAMETER TABLE.jpg (482×566) Wood screws, Wood

WOOD SCREW DIAMETER TABLE.jpg (482×566) Wood screws, Wood

Metric Bolt Actual Dimensions Useful Charts and Visual

Metric Bolt Actual Dimensions Useful Charts and Visual

Screw Sizes Charts and other Resources Metal working

Screw Sizes Charts and other Resources Metal working

Wood screw sizing chart Reference chart, Chart

Wood screw sizing chart Reference chart, Chart

Kreg Jig settings chart for pocket hole screw size Kreg

Kreg Jig settings chart for pocket hole screw size Kreg