How to modernize combinatorial chemistry

The BIOVIA customer described in this article is one of the world’s largest pharmaceutical manufacturers with a diverse global network of manufacturing sites and research groups. The goal of the organization is to research, develop and manufacture various medicines, vaccines and health items for consumers.

It consistently takes the lead in implementing innovative techniques to improve its R&D capabilities, increase its R&D productivity, and achieve its goal of tackling some of the most challenging problems in medicinal chemistry.

Challenge: Efficient selection of new lead compounds

The selection of drug-like compounds to use as a starting point for a new lead compound is a major challenge for medicinal chemists working in the life sciences sector. Candidates must meet several key criteria, including size, synthesizability, and safety.

Drug companies can now assemble virtual libraries of related compounds thanks to combinatorial chemistry, making it easier for researchers to focus on the compounds that best meet their needs.

A large team of medicinal and computational chemists had previously been tasked with managing this BIOVIA customer’s combinatorial library, which contained tens of thousands of different compounds.

This library has had to be updated frequently to reflect recent changes in regulatory and R&D strategy. The management team therefore had to evaluate the millions of compounds available from different suppliers and narrow them down to meet the client’s required parameters.

The client took a highly selective, three-phased approach to potential new compound purchases to ensure candidate compounds met researchers’ requirements. It focused on selecting candidates based on various business objectives (e.g. cost) and specific physico-chemical descriptors. This process was repeated every year.

However, maintaining the right balance between these commercial and scientific goals often resulted in screenings being performed multiple times. These unsuccessful runs led to increased pressure to complete projects on time and within budget, reducing productivity and increasing the possibility of analysis errors.

Running the library cost these customers tens of millions of dollars annually. To solve this problem, company management decided to investigate techniques to automate the labor-intensive, unprofitable steps of the process in order to streamline the selection of compounds for the library.

We have written screening templates and tools within (BIOVIA Pipeline Pilot). This is the least expensive tool I’ve ever had. It completely saved our minds.

Director, R&D, global pharmaceutical manufacturer

Solution: Pipeline Pilot to automate candidate screening

For the customer’s high-throughput screening processes, BIOVIA Pipeline Pilot partitions its data across its wide variety of chemical compounds and controlled substances. This has enabled a pharmacophoric approach to candidate selection and helped reduce potential problems with legislative changes.

Pipeline Pilot enabled this customer to achieve their goals of archiving connection collections based on various criteria such as: B. desirable physico-chemical properties, molecular complexity and synthesis costs.

Based on a specific portfolio of targets and potential compounds, the customer was able to estimate which compound in their library would yield the greatest yield by building a mathematical model within BIOVIA Pipeline Pilot that parameterized historical screening data.

The customer was able to more easily manage its supply chain from external companies. Through filters and caches created in Pipeline Pilot, the team removed bugs in the ingestion processes and connection collection logs.

The client has reduced employee turnover and streamlined procedures by removing the tedious roadblocks associated with these processes. A team member claims that this is the case “completely saved her sanity.”

Result: A streamlined process for combinatorial chemistry

The customer used BIOVIA Pipeline Pilot to create efficient protocols to streamline their chemical compound collection processes. It eliminated several bottlenecks in its automation facilities, lowered total cost of ownership, and finally completely changed the scope of its processes.

With these transitional adjustments, the customer increased their compound library by 55% and reduced maintenance expenses by over 50%.

This client’s team now has efficient and effective access to high-throughput screening data and an automated and improved input method for determining chemical compound collection. This has resulted in improved synchronization and continuous review of compound collection procedures.

Photo credits: BIOVIA, Dassault Système

About BIOVIA, Dassault Systèmes

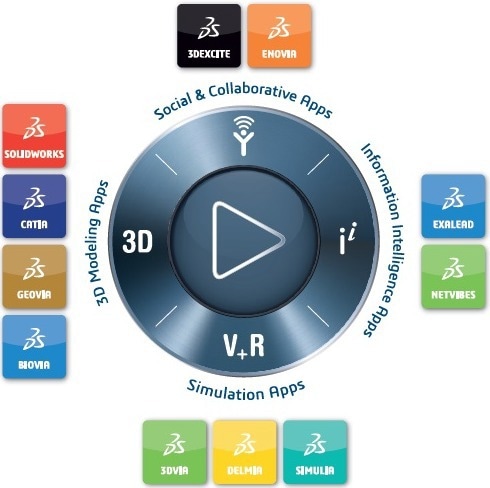

BIOVIA™ provides global, collaborative product lifecycle experiences to transform scientific innovation. Our solutions create an unmatched science management environment that can help science-based organizations create and connect biological, chemical and material innovations to improve the way we live.

The industry-leading BIOVIA portfolio integrates the diversity of science, experimental processes and information requirements end-to-end across research, development, QA/QC and manufacturing. Skills include scientific informatics, molecular modeling/simulation, data science, laboratory informatics, formulation design, BioPharma quality and compliance, and manufacturing analysis.

BIOVIA is committed to improving and accelerating innovation, increasing productivity, improving quality and compliance, reducing costs, and accelerating product development for customers across multiple industries.

Sponsored Content Policy: News-Medical.net publishes articles and related content, which may be from sources with which we have existing business relationships, provided that such content adds value to News-Medical.Net’s core editorial ethos, which is to promote medicine educate and inform interested site visitors about research, science, medical devices and treatments.