How to Solder Header Pins on a Raspberry Pi Pico

Microcontrollers are becoming increasingly popular for electronics projects and the Raspberry Pi Pico is an exciting addition to the range of boards available. With its 32-bit dual ARM Cortex-M0+ RP2040 chip, it packs a lot of performance into a tiny package at a very low price.

The only problem with the Pico is that header pins are not connected to its GPIO header by default (unless you get the Pico H version). This means you need to solder two rows of 20 header pins onto the board. The good news is that this process is easier than you think.

Getting ready

Before diving into soldering, let’s review what you’ll need.

- Fine-tipped soldering iron, a soldering iron stand, and a sponge (to wipe excess solder off your soldering iron)

- Raspberry Pi Pico (or Pico W)

- 2x 0.1″ pitch 20 pin headers (these are often supplied in pico header kits)

- solder wire

- Old circuit board for practice (optional but recommended)

- Solder sucker (optional but useful when fixing your bugs)

- Robust surface to work with

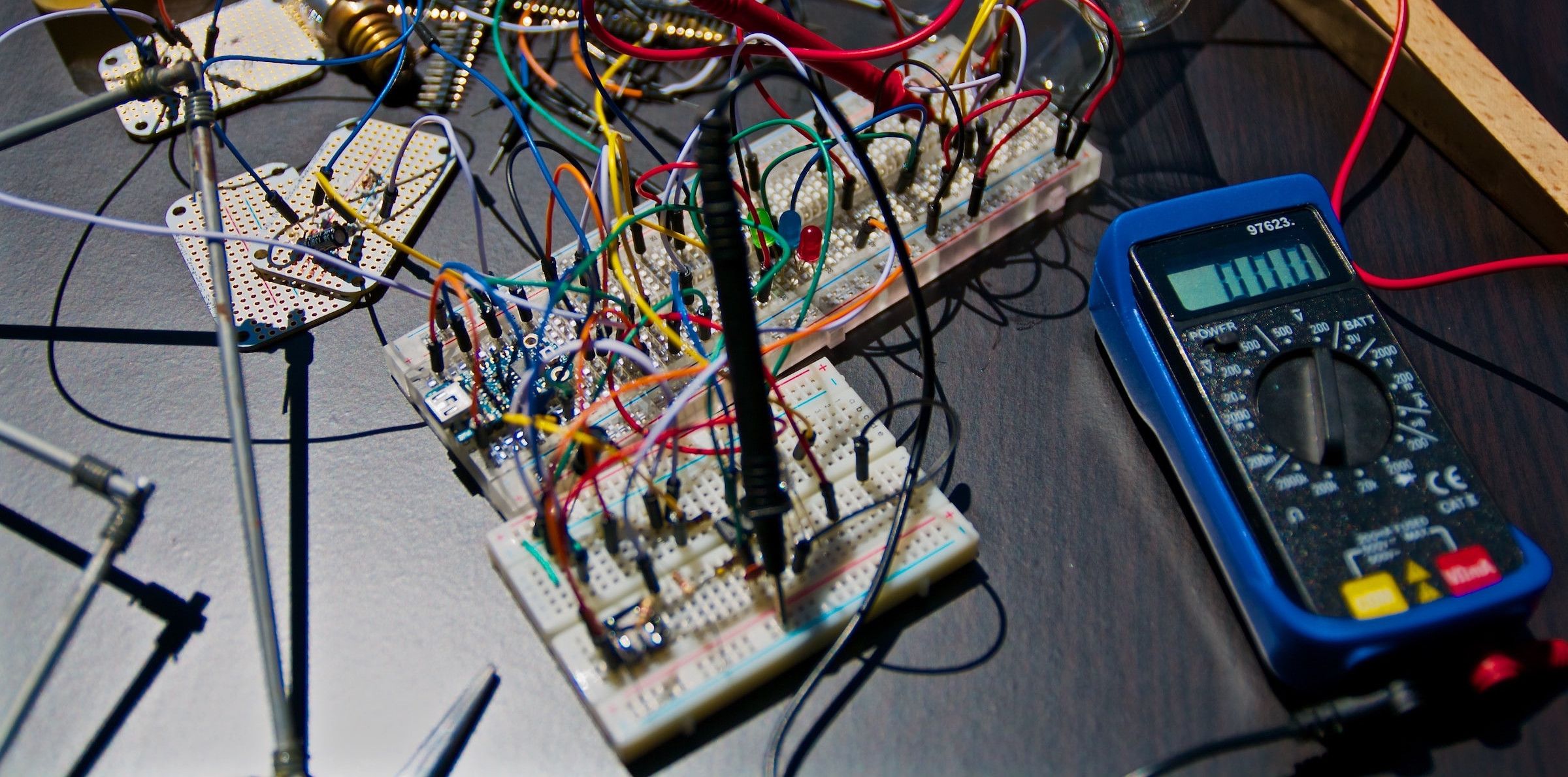

Practice creates masters

The best way to perfect your soldering skills is to grab an old circuit board and use the techniques you’ve researched online, such as B. our guide to soldering wires and electronics. Use the available digital content and watch some YouTube demonstrations until you are ready to try soldering for the first time.

Also, make sure your iron is at the right temperature when soldering. Worst case scenario, if you make a mistake, you can use a solder sucker to fix your mistake.

solder on!

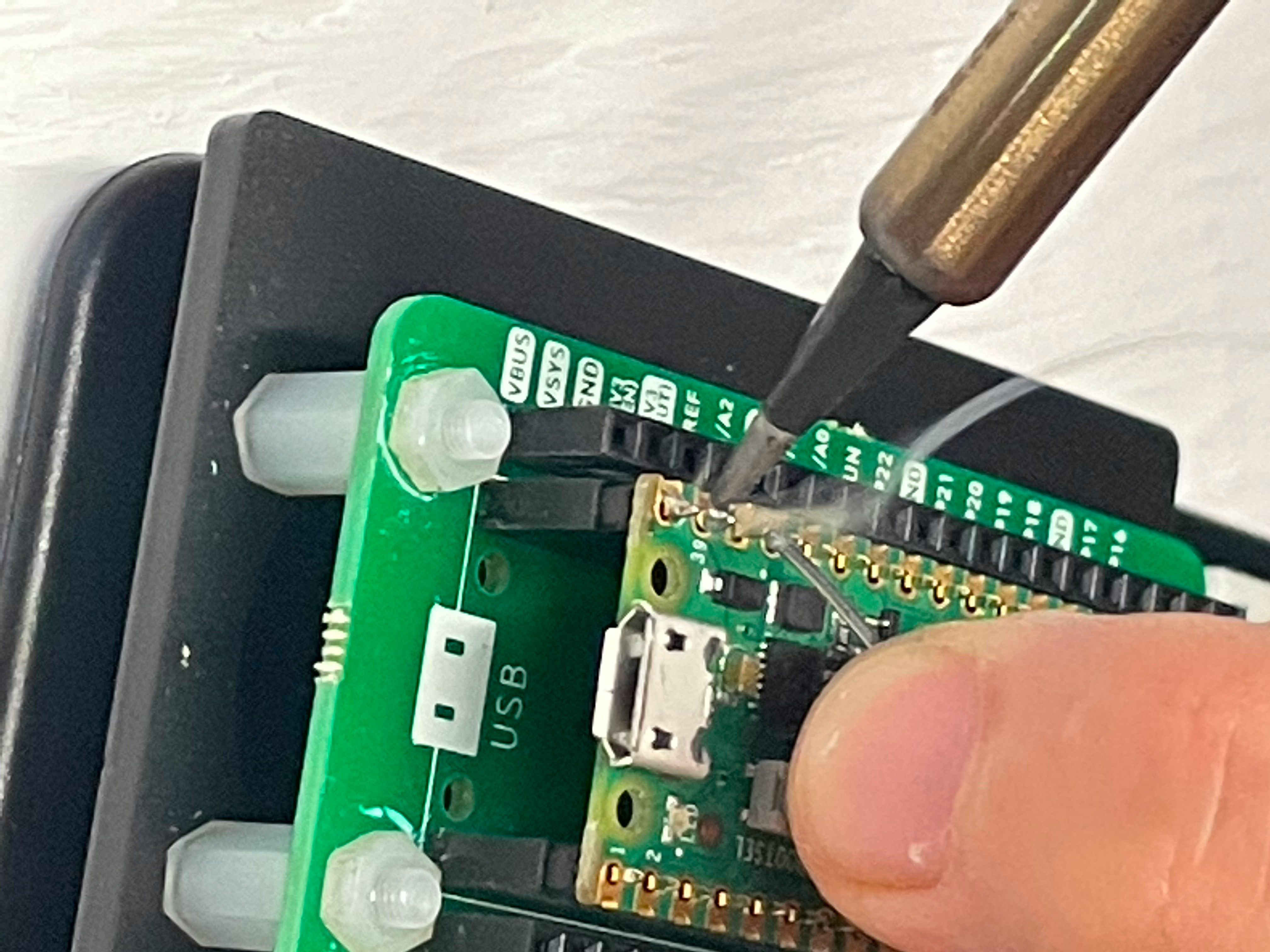

In this example, attaching the Pico to a Kitronik Inventor’s Kit proved to be a great platform to keep the board from moving on the header pins when soldering. Any Pico add-on with female headers would work, or you could use a standard electronics breadboard to hold it in place. Additionally, it’s ideal if you have a 3D printed clamp or other way to keep the board from moving.

If you don’t have a temperature gauge on your soldering iron, you can tap the soldering iron tip on a nearby sponge a few times. Usually the hissing is an indication that your soldering iron is hot enough to melt the solder wire on the pins.

Place your soldering iron tip at about a 45 degree angle to the header pins, making sure the tip is making contact as well. Hold the soldering iron tip in place for 1-2 seconds and then lower the wire to just above the soldering iron tip and allow the wire to puddle slightly. If you notice that the area around the pin is covered, remove the wire and then gently lift the soldering iron. Repeat this process until you have completed these steps for all 40 header pins.

did you make a mistake Take a break and dive into this guide detailing soldering best practices. So you know exactly what to do when something goes wrong.

Start creating

Now that you’ve mastered the basics of soldering, all you need to do is practice and get to work creating some great projects. The Raspberry Pi Foundation website has a series of step-by-step project tutorials for you to dive into. You can also check out our guide to projects for a Raspberry Pi Pico for inspiration.

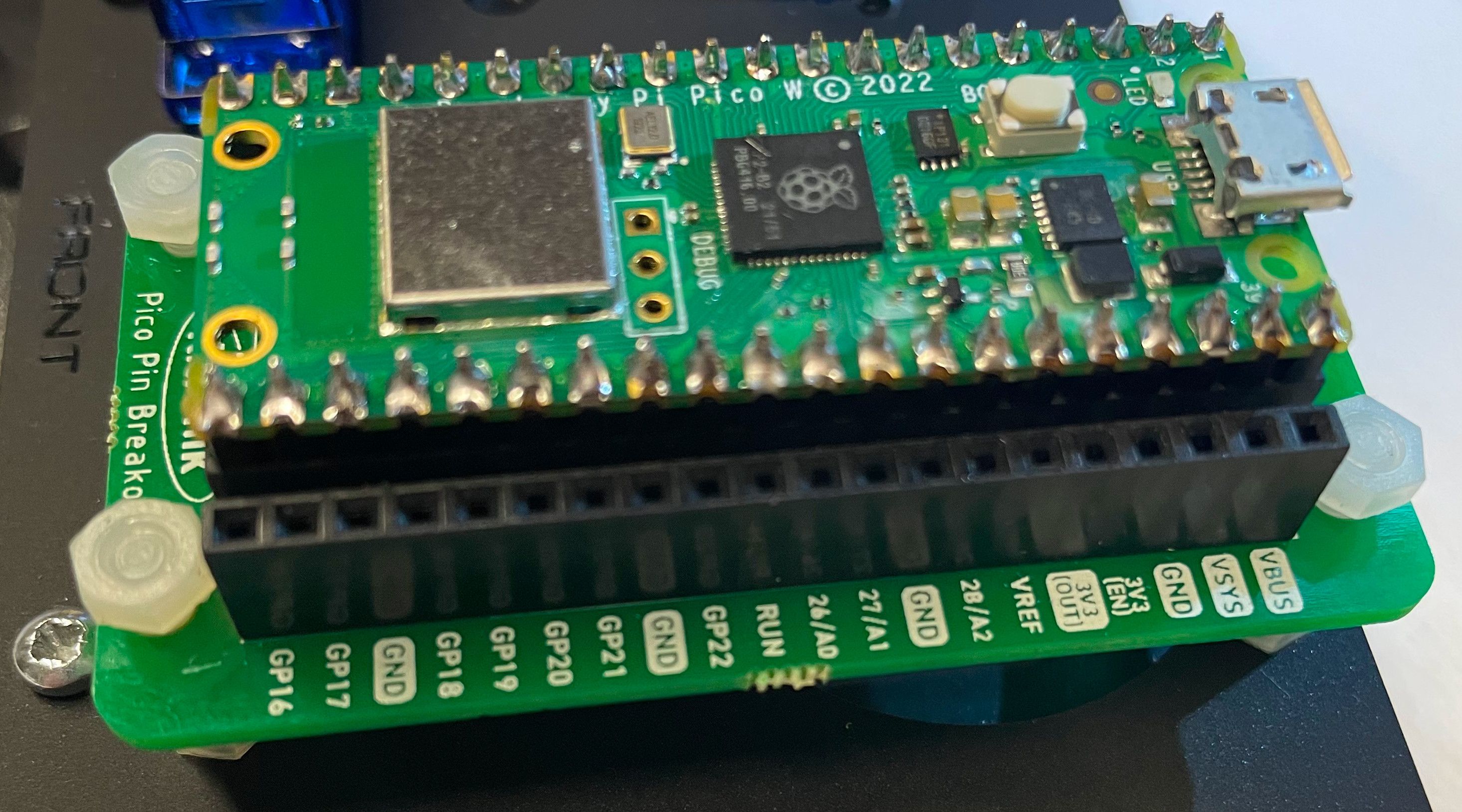

Pico with soldered pins

Now that you have pin headers attached to your Raspberry Pi Pico, you can more easily connect it to a variety of add-on boards and electronic components. What you create with it next is entirely up to you. If you have the Pico W version with built-in wireless connectivity, you can also use it for IoT projects.