“Inject less, retain more quality” – GEA Food Solutions on their latest OptiFlex needles that don’t clog, bend or break

OptiFlex needles flex and recover their shape rather than bending or breaking when encountering bone-in parts, resulting in no bent needles and optimal injection performance for ham and bacon. OptiFlex needles also prevent clogging, reduce waste and improve production processes, resulting in significant benefits for their customers.

Wim Sturm, Product Sales Manager at GEA Food Solutions, discusses the benefits for operators using OptiFlex.

They describe GEA Optiflex needles as a “major advance in injection quality”. How are Optiflex needles different?

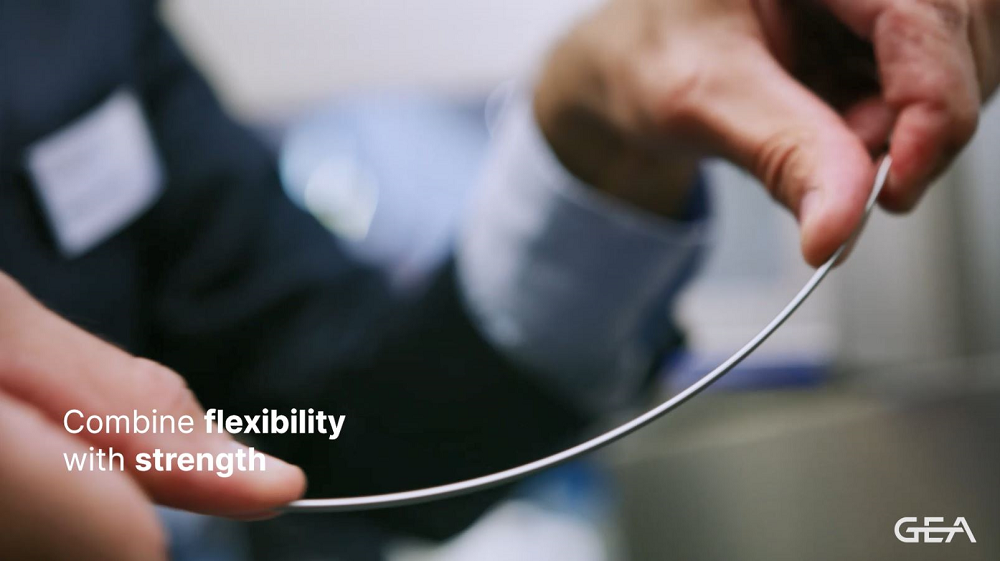

Wim Sturm: What makes them unique is the patented metal alloy that is used. Optiflex needles have “shape memory”. When you inject, and especially with bone-in products, the needle can deflect off the bone and you get a bend in the needle. With normal standard stainless steel needles, the curvature will remain in this position if it is too large. Our Optiflex needle deflects it and does not harm the product. In addition, the needle returns to its original shape after being withdrawn.

Since OptiFlex needles are more resistant to bending damage, does this mean they last longer?

Wim Sturm: Yes, they are more durable. Compared to similar needles in the same application, OptiFlex last between 40-60% longer.

How can the use of OptiFlex needles in curing processes promote product quality and safety?

Wim Sturm: There are three things to consider. First: the product to be injected, second the machine and third the operator. If we look at the product, because the needle regains its shape, it always injects in the same position. If the needle is bent, it will not inject where it should when going down. So this is a great advantage for the product. This is particularly important for brine dispersion. If you inject with a bent needle, that needle can go in the same place [as another needle] So you’re injecting twice, which would mean your brine distribution isn’t optimal. Causes potential differences in product taste, color and microbiological product safety and affects shelf life.

Second, from a machine point of view, if you have bent needles, you start damaging your machine, such as the needle guide plates (stripper plates). Third, there is operator safety. If you bent needles, they could start to break. Because OptiFlex needles will bend and return to their original shape, this is very unlikely.

Available in 2, 3 and 4mm diameters, OptiFlex needles work in a tight pattern. Why is this beneficial?

Wim Sturm: The 2mm needles are typically used for tender meats such as poultry, tender beef, pork and fish. For denser meat you will need a stronger, more durable needle, so you would switch to 3 or 4mm needles. We have an overlap pattern, and the needle-to-needle distance for 2mm injection is about 7mm, which is very tight. This means you can inject at lower pressures. If you inject with high pressure, you will disturb the meat fibers. The lower you can keep that pressure, the less damage you do and the better product you get.

How does this affect salt distribution?

Wim Sturm: Due to the small distance between the two needles, the brine distribution is optimized compared to conventional methods. Again, the less pressure you have to apply, the easier it will be balanced within the product. You get a better distribution of the nitrate salts and also a better and faster coloring. This is also important in terms of durability. With bacon, it’s important that the brine is injected and distributed evenly, otherwise you could have a problem cutting later.

On machines like the GEA MultiJector, how does the filter technology work with the needles to reduce downtime for cleaning?

Wim Sturm: The filter technology we use prevents particles from passing through the needle. But we have another special filtration system – a gravity-assisted system called a “screen filter” that allows us to filter out proteins as the brine is recirculated from the injector. This means we can use the same brine longer – because it’s cleaner – with less filter blocking and less needle blocking.

How do MultiShakers that provide transport, product distribution, brine settling and excess brine removal in injection lines work to activate ingredients and reduce yield losses?

Wim Sturm: For example, Bacon would have a flip-over conveyor belt and then the first MultiShaker is supposed to close the pinholes, trapping the injected brine in the product and activating the ingredients you just injected, like nitrate salts, phosphates, in the brine. It also removes excess brine that is on the surface of the product and dries it. This excess brine can be returned to the injector, which saves on brine losses. Sometimes we have a second MultiShaker to increase shake time and increase activation of ingredients and proteins resulting in improved sole retention.

This second shake also means less flushing (drip) after the injection. This is a natural process that we can limit by using a MultiShaker. This means fewer drips on the floor, less cleaning and fewer risks of cross-contamination further down your production line. It also means less yield loss. If you weigh the product after the shaker, you know there is (the brine) in it, so you have a more accurate measurement. Your downstream process may involve tumbling and this can allow for shorter tumbling times – this is a time saver and potentially increases your tumbling capacity in the process.

What feedback have you received from the industry?

Wim Sturm: We received some particularly valuable feedback. The less waste you have, the more time you save cleaning. The less handling you have, the less brine will spill. The more parameters you can control, the more control you have over the result. The bottom line is that your competitive advantage should lie in optimal process and production. Our goal is to provide our customers with the best options so they can achieve the best results.

To learn more about this innovation, download the white paper below.