Research team discovers how to convert 3D-printed polymer to stronger, ductile hybrid carbon microlattice material

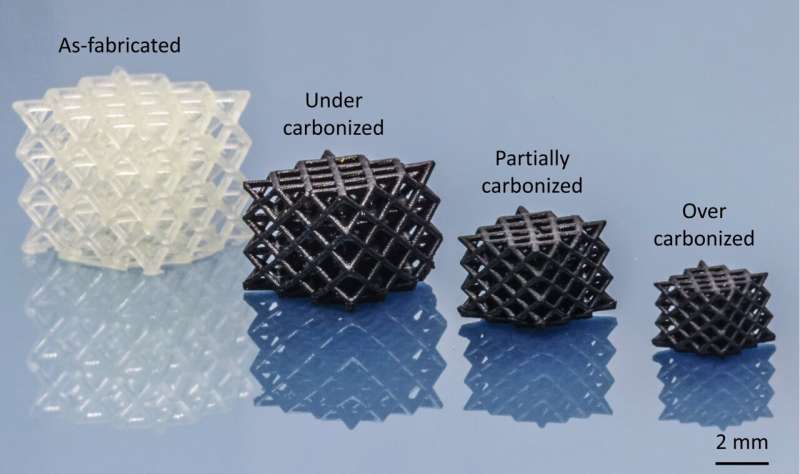

The four main types of samples examined in this work, namely as fabricated, undercarbonized, partially carbonized, and overcarbonized microlattices. Photo credit: James Utama Surjadi et al., matter (2022). DOI: 10.1016/j.matt.2022.08.010

The development of a lightweight material that is both strong and highly ductile is a long-sought goal in the field of structural materials, but these properties are generally mutually exclusive. However, researchers at the City University of Hong Kong (CityU) recently discovered a low-cost, direct method to convert commonly used 3D-printable polymers into lightweight, ultra-hard, biocompatible hybrid-carbon microlattices that can be of any shape or size. and are 100 times stronger than the original polymers. The research team believes this innovative approach to manufacturing sophisticated 3D parts with tailored mechanical properties can be used for a variety of applications including coronary stents and bioimplants.

Metamaterials are materials engineered to exhibit properties not found in naturally occurring materials. 3D architectural metamaterials such as microgrids combine the advantages of lightweight design principles with the intrinsic properties of their materials. Manufacturing these microgrids often requires advanced manufacturing technologies such as additive manufacturing (commonly referred to as 3D printing), but the range of materials available for 3D printing is still fairly limited.

“3D printing is becoming a ubiquitous technology for manufacturing geometrically complex components with unique and tunable properties. Strong and robust architectural components usually require metal or alloy 3D printing, but they are not easily accessible due to the high cost and low resolution of commercial metal 3D printers and raw materials. Polymers are more accessible, but typically lack mechanical strength or toughness. We found a way to turn these weaker and brittle 3D-printed photopolymers into ultra-strong 3D architectures comparable to metals and alloys, simply by heating them under the right conditions, which is surprising,” said Professor Lu Yang from Department of Mechanical Engineering (MNE) and Department of Materials Science and Engineering (MSE) at CityU, who led the research.

A new method of increasing strength without sacrificing ductility

The most effective approach to date to increase the strength of these 3D printable polymer lattices is pyrolysis, a thermal treatment that converts the entire polymers into ultra-strong carbon. However, this process robs the original polymer lattice of almost all of its ductility, creating an extremely brittle material like glass. Other methods of increasing the strength of the polymers also typically result in a decrease in their ductility.

The team led by Professor Lu found a ‘magic’ state during the pyrolysis of the 3D-printed photopolymer microlattices, resulting in a 100-fold increase in strength and a doubling of the ductility of the original material. Their results were published in the scientific journal matter entitled “Lightweight, Ultra-tough 3D Architected Hybrid Carbon Microlattices”.

They discovered that by carefully controlling the heating rate, temperature, duration, and gas environment, it is possible to simultaneously drastically improve the stiffness, strength, and ductility of a 3D-printed polymer microlattice in a single step.

Coronary stent demonstration with the 3D printed partially carbonized core. Photo credit: James Utama Surjadi et al., matter (2022). DOI: 10.1016/j.matt.2022.08.010

Through various characterization techniques, the team found that simultaneous improvement in strength and ductility is only possible if the polymer chains are “partially carbonized” by slow heating, where an incomplete conversion of the polymer chains into pyrolytic carbon occurs, creating a hybrid material in which Both loosely crosslinked polymer chains and carbon fragments coexist synergistically. The carbon fragments act as reinforcing agents, strengthening the material, while the polymer chains limit the composite’s fracture.

The ratio of polymer to carbon fragments is also critical to achieve optimal strength and ductility. If there are too many carbon fragments, the material becomes brittle, if there are too few, the material lacks strength. During the experiments, the team successfully created an optimally carbonized polymer lattice that was over 100 times stronger and more than two times more ductile than the original polymer lattice.

Benefits that go beyond improving mechanical properties

The research team also found that these “hybrid carbon” microlattices exhibited improved biocompatibility compared to the original polymer. Through cytotoxicity and cell behavior monitoring experiments, they proved that the cells cultured on the hybrid carbon microgrids were more viable than the cells seeded on the polymer microgrids. The enhanced biocompatibility of the hybrid carbon lattices implies that the benefits of partial carbonization go beyond improving mechanical performance and may potentially improve other functionalities as well.

‘Our work provides an inexpensive, simple and scalable way to fabricate light, strong and ductile mechanical metamaterials of virtually any geometry,’ said Professor Lu. He envisions that the newly invented approach can be applied to other types of functional polymers and that the geometric flexibility of these architectural hybrid carbon metamaterials will allow their mechanical properties to be optimized for a wide range of applications, such as biomedical implants custom-design robust scaffolds for micro-robots, energy harvesting and storage devices.

Professor Lu is the corresponding author and Dr. James Utama Surjadi, a postdoc in his group, is the first author of the work. The collaborators include Professor Wang Zuankai, Chair Professor in the MNE Department, and Dr. Raymond Lam Hiu-wai, associate director and associate professor in CityU’s Department of Biomedical Engineering.

Researchers 3D print the first high-performance nanostructured alloy that is both ultra-strong and ductile

James Utama Surjadi et al., Lightweight, ultra-hard hybrid carbon microlattices with 3D architecture, matter (2022). DOI: 10.1016/j.matt.2022.08.010

Provided by City University of Hong Kong

Citation: Research Team Discovers How to Convert 3D-Printed Polymer Into Stronger, Ductile Hybrid Carbon Microlattice Material (2022 September 7) Retrieved September 7, 2022 from https://phys.org/news/2022-09-team -3d-printed- polymer-stronger-ductile.html

This document is protected by copyright. Except for fair trade for the purpose of private study or research, no part may be reproduced without written permission. The content is for informational purposes only.